The George Winter High Bay

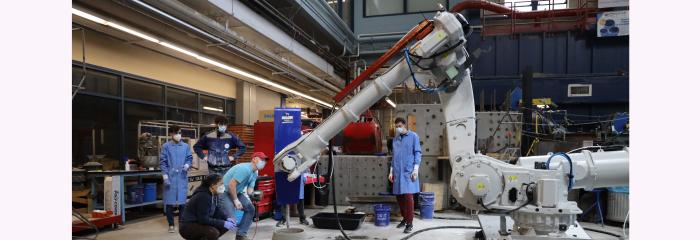

The George Winter High Bay is home to the seven-axis ABB robot and the Cornell 3-meter biaxial direct shear apparatus. CEE students receive hands-on experience, designing, setting up and performing tests, and recording and analyzing real life data. The ability to observe these events in real time creates a total package of both practical and theoretical knowledge, increasing the understanding and enthusiasm of the students.

The seven-axis ABB robot and an xHEAD, printing head, developed by XtreeE, is being utilized for 3D mortar printing. Rhino and Grasshopper software are being employed for creating the printing files. A 3D model is created, then deconstructed into a matrix of points with X, Y, and Z coordinates. The robot communicates with the xHEAD to synchronize the speed of the robot and the feed rate of the xHEAD as the robot follows the path of points. Several factors need to be considered when printing, such as; material viscosity, curing rate, hardening rate, shrinkage, strains, size and shape of structure, temperature, humidity, along with others.

Professor Nair and her research group are developing new cementitious mix designs or 3D concrete printing (3DCP). The Nair Group is also researching the implementation of larger aggregates and steel fibers into their mix designs for 3DCP. With the large range of the system, full size structural members such as beams, slabs, and bridge members with dimensions of 2 m x 10 m (~6 ft x 33 ft) may be printed. Once structures are printed and cured they may be tested in the large-scale structural testing area contained within the Bovay Laboratory Complex.

The 3D printer will be integrated into labs for the new course on Sustainability and Automation: The Future of Construction Industry. In the near future the seven-axis robot will be utilized or supporting additional courses and faculty research programs. The system also has the potential for performing structural manufacturing processes such as welding, plasma cutting, material handling, and assembly.

Earthquakes and landslides cause overwhelming damage, injury and death, and cannot be controlled by humans. Better understanding earthquakes through research will help us create safer and more resilient structures, develop early warning systems, and estimate short-term and long-term seismic hazard.

The Cornell 3-meter biaxial direct shear apparatus that consists of a 3-meter-wide, 4.9-meter-long, steel load frame and two banks of hydraulic cylinders capable of applying 32 MN (3597 tons) of force to a 3-meter-long slab of Barre gray granite. This apparatus is the largest of its kind in the world and is utilized to generate small scale earthquakes.

The 3-meter device is used by the McLaskey Research Group study the way that dynamic fault rupture events initiate, propagate and terminate including the seismic waves that are radiated by the rocks during these processes. Students and faculty study the mechanics of fault rupture and the physical mechanisms by which faults and fractures generate seismic waves.